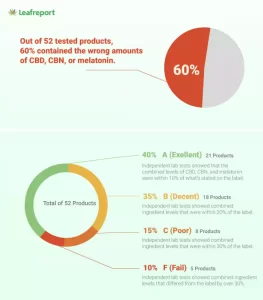

Out of 52 tested products, 60% contained the wrong amounts of CBD, CBN, or melatonin. One product contained no melatonin at all and two others had 3-5 times more than advertised.

CBD sleep products are becoming increasingly popular and sophisticated. Many contain not just CBD but other active ingredients, with melatonin and the minor cannabinoid, cannabinol (CBN), being the most popular.

But do these products actually contain what it says on the label? Are their levels of active ingredients accurate?

To find out, Leafreport bought 52 CBD sleep products and sent them to an accredited third-party cannabis testing lab called Infinite Chemical Analysis Labs. Most of these came in the form of gummies, tinctures, or capsules.

We compared the lab’s findings to the amounts of CBD, CBN, and melatonin listed on the product label and description. Here’s what we found…

Did recalled Missouri cannabis products pose health risks? Regulators aren’t sure

by ICALadmin | Sep 18, 2023 | Press

By Rebecca Rivas

Lab experts say the state’s mandated testing process for marijuana is not designed for the chemicals used to convert hemp CBD to THC.

Marijuana dispensaries and warehouses across Missouri are holding on to more than 62,000 products in special vaults.

The state suspects that they were infused with a questionable THC concentrate, or distillate, purchased from a Robertsville-based licensed marijuana manufacturer called Delta Extraction.

Delta Extraction is fighting to get the Aug. 14 recall overturned — and one of the company’s main arguments is that the products were tested by state-licensed labs and don’t pose a health risk that would require a full recall.

Delta’s general manager Jack Maritz told the Administrative Hearing Commission on Aug. 14 that the distillate has been distributed throughout the entire state of Missouri for more than a year.